UnofficialBMW.com

Adding an OBC to an E36 3-Series

ADDING AN OBC

TO AN E36 3-SERIES

This is the second of a two part article

on adding an OBC to an E36 3-series. The first

part explained how to

add European-style parking lights, which is a natural project to

combine with this one since it shares much preliminary work and because

the car needs a different turn stalk if you wish to use it control the

OBC.

An On Board Computer (OBC) can be a useful and amusing accessory, and

in many parts of the world you can order one on any BMW you might

consider. In the United States, however, an OBC is often not an option

until a car has at a least six cylinders. No doubt there are many

owners of 3-series limousines, coupes and cabriolets who would like to

have an OBC, an option that is technically feasible.

This article shows how to add an on board computer to a U.S. market,

standard body E36 3er that did not come with one. The instructions have

been checked against cars built in 1995 and 1996, but likely apply to

early and later model years with possible modifications. The

retrofitting requires some mechanical and electrical skill and probably

should not be attempted unless you are comfortable modifying your car's

electrical system. If the quality of the work is not at least as good

as the factory's, you may have to pay for the consequences should

something later go wrong. The job is not very involved, however, so the

cost of having a journeyman do the work should not be too high.

These instructions assume your car already has an outside temperature

display. They explain how to wire up an OBC to provide most of its

basic functions, everything but check control, the CODE function, and

parked car ventilation. Enabling these functions takes more

effort. The adventurous can consult the Electronic

Troubleshooting Manual for the appropriate year, chiefly section

6581.2. Be warned that the drawings have a fair number of errors and

that it pays to compare ETM's for other model years and other markets.

These instructions draw on the U.S. and German ETM's for 1995 and 1996.

As in previous article about parking lights, the information in this

article has been segregated into two parts: a set of specific

instructions for retrofitting an on board computer and a collection of

more generally useful notes that explain the instructions. The notes

are numbered, and the instructions cite them as they become useful as:

$2.1, $2.2, .... To save space, the instructions also cite note's from

the European parking light article as:

$1.1, $1.2, ....

PARTS LIST

Quant.

|

Item

|

1

|

On board computer (GB/USA), BMW

65 81 8 357 684

|

3

|

Comb terminal contact sleeves

for 0.35-0.5 mm2 wire, BMW P/N 61 13 1 387 140)

|

1

|

Wire end with contacts for

(brown) Siemens socket connectors, BMW P/N 61 13 0 005 201 (part of

Repair Set H, Cartool BMW 61 9 058)

|

6

|

Wire ends with contacts for

(black) AMP socket connectors, BMW P/N 61 13 0 005 197 (part of Repair

Set H.) |

1

|

18 pin AMP socket connector

assembly consisting of: a black contact housing, BMW P/N 61 13 8 364 666,

and an unkeyed water green strain relief shell, BMW P/N 61 13 8 364 662 |

1

|

OBC turn stalk that matches the

car* (see $1.1) |

1

|

wired 2.5 mm round male contact

for 0.5-1.0 mm2 wire*, BMW P/N 61 13 0 007 449 |

(*) You may omit the starred items if you do not wish to

install an OBC turn stalk. The stalk allows you to cycle through the

OBC modes as discussed in the owner's manual. A survey of BMW-digest

readers found a nearly even split between those who really like such

stock control and would add it to their next car and those who find it

useless and would omit it.

Along with the usual tools, you will need a Torx T20 driver to remove

the instrument cluster ($2.2), a long thin T10 driver to run wires to

the fusebox ($1.12) and a 16 mm socket and a thin T25 driver to remove

the steering wheel and airbag ($1.8).

PROCEDURE

1. Read

out any DME fault codes and then disconnect the battery. BMW recommends

you read the codes but this is not crucial.

2. Remove the outside temperature display ($2.1). Unclip the storage

compartment underneath and push it to the right.

3. Remove the driver's kick panel and knee protection ($1.7).

4. Lift and unclip the black terminal/relay block on the front left

wall above the driver's footrest (parking

light article, step 4). Rotate the block so that you can add to its

wires.

5. Remove the steering wheel and airbag ($1.8).

6. Remove the instrument cluster ($2.2).

7. If you are installing an OBC turn stalk, change the turn stalk and

remount the four steering column connectors ($1.2).

8. Construct and lay the supplementary harness (later section and $2.5).

9. With the harness in place, move the following wires from the

original temperature display connector to the new OBC connector:

Move

|

Wire Color

and Function

|

To

|

| X1070

pin 17 |

0.5 mm2

brown ground wire |

X1071

pin 13 |

| X1070

pin 18 |

0.5 mm2

red/yellow B+ wire from F31 |

X1071

pin 8

|

10. Reassemble connectors X1070 and X1071 and tidy up the wiring. The

new X1071 connector is unkeyed and will fit the wrong socket on the

OBC. To make sure of what it is going into, first plug the black

connector, X1070, into the black, passenger side socket; then plug

X1071 into the natural-color, driver side socket.

This

schematic summarizes the conversion.

This

schematic summarizes the conversion.

11. Clip the terminal/relay block back on to the left wall. Reinstall

the instrument cluster, steering wheel and airbag ($1.9). Make sure no

one is in the car and reconnect the battery.

12. Turn the ignition key to position one, the accessory position. A

brand new, uncoded OBC will display P

P P P. You now need to visit the dealer and make use of their

DIS computer. First have the dealer run diagnostics on the OBC. You may

see the following faults:

Central

check control light

Gong

T2

Gong

T1

Code-Function

Timer

Terminal

50

All

these “faults” are normal: the first if the car doesn't have check

control, the second and third because you disconnected them, the fourth

because you have not connected the drive-away protection, the fifth

because the car doesn't have parked car ventilation, and the last,

because you did not connect the OBC to the starter motor, assuming you

constructed the suggested harness. (If you decide to add parked car

ventilation or the CODE function, be sure to make the connection as

shown in the ETM.)

13. If your wiring checks out, have the dealer code the OBC and place a

new central code sticker under the back seat bench. A Meister may tell

you that this is impossible. Actually, it is just a little uncommon,

and a matter of finding the right menu. Then road test the OBC. At the

very least, verify the CONSUMption, TEMPerature, SPEED and RANGE

functions, and the turn stalk switch if you have added it. Once you are

satisfied everything works, reinstall the knee protection, the

diagnostic connector, the driver side kick panel with chimes and the

steering column shrouds.

Enjoy your on board computer.

ACKNOWLEDGEMENTS

I would like to thank Thomas Fiebig (Bobrink GmbH), Allan Rhodes,

Jr. (Bluegrass Honda/BMW), Ron Stygar and Terry Donohue for

providing parts and practical information that made the OBC conversion

possible.

SUPPLEMENTARY HARNESS

1. ADD A WIRE to X1070 pin 9 only if it missing. If you are

adding parking lights or do not mind running a wire to the fusebox ($1.12),

wire:

X1070

pin 9

A-------.5 mm2 GN/BL------[ X1076

Otherwise:

X1070

pin 9

A-------.5 mm2 GN/BL------* X17 pin 4

2. IF YOU WISH to control the OBC from the turn stalk, wire:

X1071 pin 4 A------.35 mm2

BR/RT------R X32 pin 10

3. IN ALL CASES, wire:

X1071 pin 5 A------.35 mm2

WS/VI---------------------[ X183

X1071 pin 6 A-------.5 mm2

WS/SW------* X16 pin 21

X1071 pin 7 A------.35 mm2

WS/GE---------------------[ X182

X1071 pin 9 A------.35 mm2

WS/GR------S X17 pin 10

SYMBOLS AND WIRE COLORS:

A - AMP contact

($2.4)

BL blue RT red

R - 2.5 mm round male contact

($1.4) BR brown SW black

* - Splice to wire

($2.6)

GE yellow VI violet

S - Siemens contact

($2.4)

GN green WS white

[ - Contact sleeve

($1.11)

GR grey

COMPONENTS AND LOCATIONS:

X16 is the 26 pin, white connector

you removed from the back of the instrument cluster; you will splice

into one of its wires and possibly a wire going to connector X17.

X17 is the 26 pin, blue

connector you removed from the instrument cluster; you will also add to

it a wire with the one Siemens contact.

X32 is the 12 pin, white, male

turn stalk connector ($1.5).

X182 and X183 are comb terminal junctions in

the left wall relay/terminal block.

X1070 is the 18 pin, black

connector that plugged into the passenger side socket of the outside

temperature display.

X1071 is the new, 18 pin

connector that will plug into the driver side socket of the OBC; it

will take the five or six AMP contacts.

X1076 is a comb terminal

junction in the fusebox.

NOTES

2.1 REMOVING

THE OUTSIDE TEMPERATURE DISPLAY

.

.

If you have a late model car, feel along the top of the storage

compartment immediately below the display for a hole giving access to a

compressible retaining bar. Press up on the bar to retract its

ears holding in the bottom of the display, and while pressing, pull or

gently pry the display out of the console. If you have an older car,

insert a 1 mm feeler gauge or blade between the top of the storage

compartment and the bottom of the display. Press the bar upward and

carefully pry out the display. Unplug the rear connector as it becomes

accessible ($2.3) and remove the display.

2.2 REMOVING THE

INSTRUMENT CLUSTER

Remove the airbag and steering wheel ($1.8). Remove the two Torx-20

screws that secure the top of the instrument cluster to the top of its

well. Gently pry down the top edge of the cluster until it comes frees,

then slide it out. Be very careful not to scratch its soft, plastic

face; clear plastic will attract all but the most carefully controlled

tool. Unclip the instrument cluster's three connectors as they become

accessible ($2.3) and remove the cluster.

2.3 UNPLUGGING HIGH DENSITY SOCKET CONNECTORS

The connectors are mated and separated with the aid of a swing

lever. Press down on the plastic tab that juts out from the outer

connector shell and locks the lever. Swing the lever over the tab

and away from the vertical. Continue swinging until the lever is

horizontal; then remove the connector. To plug the connector back in,

start with the lever fully horizontal.

2.4 ADDING

AND REMOVING HIGH DENSITY SOCKET CONNECTOR CONTACTS

To access the contacts, slide the black retaining clip off the end the

wires exit; then gently pull on the wires and slide out the slim,

rectangular contact housing. The contacts are numbered. They have

retaining barbs which must be oriented so that they pop into the

windows on the side of the housing; the contacts will then click easily

into place. To remove a contact, use a straightened paper clip, gently

press the contact barb through its window and slide it out. It should

come out easily.

2.5

CONSTRUCTING AND LAYING THE WIRING HARNESS

Try to route the harness so that such things as the air conditioning

can be removed without cutting wires. Someday, you may appreciate your

foresight. You can use plastic ties to add to the car's existing cables

or you can slip wires under the cable tape where it is loose.

Don't worry about having some slack at the ends of the harness: you

will have room and it is better than coming out too short. Try to use

the indicated wire sizes and colors ($1.3).

You can now add wires. The contact locations are numbered and can be

read with a bright light. To add a wired contact, find the correct

position, thread the wire through the retaining shell and then click

the contact into the contact shell. Remember: through the retainer;

then into the shell. Don't forget or you may have to beg your dealer to

lend you their contact removal tool.

2.6 SPLICING

INTO EXISTING WIRES

.

.

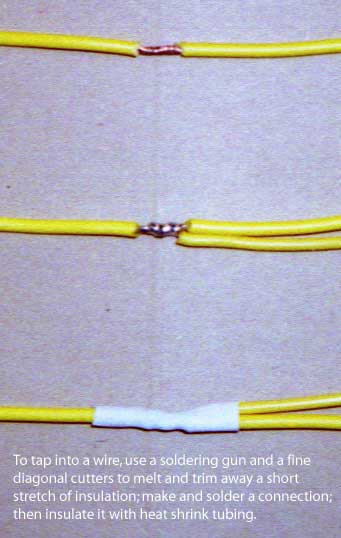

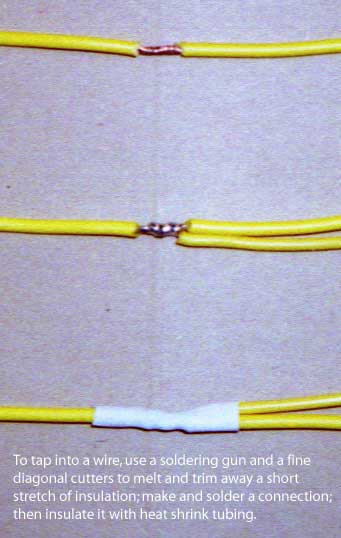

In the instructions they supply with their aftermarket products, BMW

cautions: “Never use Scotchlock

fast connectors”, as they may cause

faults in low-level electronic signals. Here is a more compact and

reliable way to splice into existing wires, for example, the B+ and

fuel consumption wires running to the instrument cluster.

Find the wire you wish to tap into and unplug it from its connector.

Unthread the wire from its harness back to the desired tap-in point.

Using a soldering gun (but probably not its tip), melt through the

insulation on both sides of the wire trying not to heat the wire very

much. Bow the wire with your fingers and separate it from the melted

insulation.

Using a fine diagonal cutters, pull back and trim away the melted and

softened insulation so that you expose a short section of bare

wire. Lay the new wire alongside the original, wrap it around the

bare section, solder the connection and insulate it with heat shrink

tubing or electrical tape (Fig. 2). Then plug the original wire back

into its connector.

Copyright © 1997, 2001 and 2009 by

John

Firestone

This

schematic summarizes the conversion.

This

schematic summarizes the conversion. .

. .

.