E30 Rear wheel bearing

replacement.

I

have a friend in town that owns his own race shop so I had access to a

lift. I also talked another friend who’s

done this before into helping me.

Hopefully, this guide, though crude, will help you get some idea of how

this job goes.

I

highly recommend using a lift on this job or just paying somebody else to do

it. It’s not fun.

Please

note that we replaced the rear axles at the same time. I believe you have to probably take them off

anyway to replace the bearings.

We

put the car up on the lift and removed the wheels.

I

have rear drum braked on my 1985 318i so removed the outer drum. Disc brake people would have to probably pull

their rotors and calipers and tuck them up into the fender well safely.

We

pulled the large retainer nut off the end of each axle using an impact wrench,

(another highly recommended tool!) I think it was about a 32mm.

Next,

we disconnected the rear axle assembly from the rear differential

They’re

allen heads.

…and

used a cold punch and a large brass hammer to pound the axle (spline portion)

out from the center of the rear wheel bearing. Mine had been in there for around 400,000

miles so they didn’t come out willingly.

Some liquid wrench or pb-blaster comes in handy here.

We

actually destroyed one of the cold punches and had to use another one and a

baby sledge.

The

threaded end of this old axle was beat to a pulp when we were done.

Luckily,

they didn’t look too closely at the parts store so I still got my core charge

back!

Often

times, when you pound these out, the hub might come out with the axle and bring

the inner race of the bearing out still on the hub. Be inventive if that happens.

The

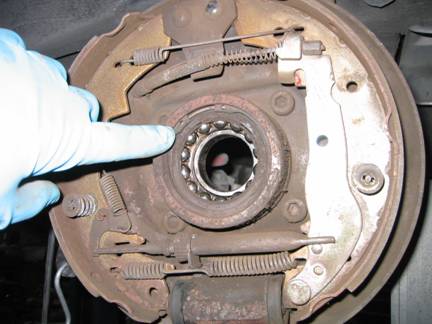

wheel hub has inner splines that match up the splines on the axle end. Here’s a picture where they go into the hub

from inside.

Here’s

a picture of the inner race still in the hub. Note the snap ring under my

finger has

to be removed.

Next,

we had to invent a type of press to take out the wheel hub. It has to come out so that you can press the

new bearing into it. Bavauto and other

places make a press tool, but we just got a length of all-thread from the

hardware store, a heavy duty piece of steel bar, and used some sockets to do it

as shown in the picture.

Or,

you can use a puller. This one was a

cheap-o model and broke on us.

We

were even gonna try this ghetto method shown below, but after getting it hooked

up and looking at it and having a good laugh, decided not to. Yes, that’s a pull-hammer.

Once

the hubs were out, we knocked out the inner race from the wheel hub.

Now

is the time to get your new pieces ready.

Clean

up the wheel hubs really well, and anti-seize the inside of them lightly.

Also,

anti-seize the outside of the new bearings.

If

you’re using re-man axles like we were, you’ll want to take a small triangle

file and make sure the splines on the new axles are in good condition. Ours were pretty beat up.

An easy

way to do this is to simply pound the hubs onto the new axles which forces the

splines to match up. Then, use a puller

too pull the hubs off the new splines.

Clean up both, and repeat this a few times. It’s a crude method, but it saves you 3 hours

of filing to try and get the splines to line up. You probably wouldn’t have the same problem

if you bought new axles, but remanufactured ones are often beat up rather badly

on the splines.

NOTE If you have the new bearings

in and go to put the axles back in, do not do it without making sure the

splines line up easily. Otherwise, when

you tap in the axle, it’ll push the wheel hub too hard and that will push out

the inner race of your brand new bearing.

And you’ll have to start back over.

We did this on one side and we weren’t happy.

Next,

press the bearings back into each side.

We simply reversed the direction of our homemade puller contraption and

pressed them into each side.

NOTE When you press in the new

bearings, make sure you only press on the outer race. The inner race will push out very very

easily. We used the old bearing as a

pressing surface so that we’d only press on the outer race. Make sure you line it up nicely (not like

shown in the picture)

After

your bearings are press in, you can press in the hubs.

This

is where it gets tricky. You have to

have something on the back (inside) of the hub to go against the inner side of

the bearing. By inner side, I mean

toward the differential.

We

used a large thick steel washer. If you

don’t have something there, you’ll pop out the inner race of the new

bearing.

So…after

seating it gently with a hammer, tapping it lightly all around the rim several

times…..press away!

Pressing

it in….

You

can kinda see the big washer on the backside here holding in the inner race.

Next,

all you do is LIGHTLY tap your axles back in. This is where you want to make sure those

splines match very easily. Then, bolt

them back up to the differential, put the brake drum (or disc and caliper) back

on, replace the wheels and you’re done!

Matt